Flexible Outsourced Manufacturing

SERVICES

Contract Manufacturing

How Contract Manufacturing can help you succeed in today’s ever changing business landscape

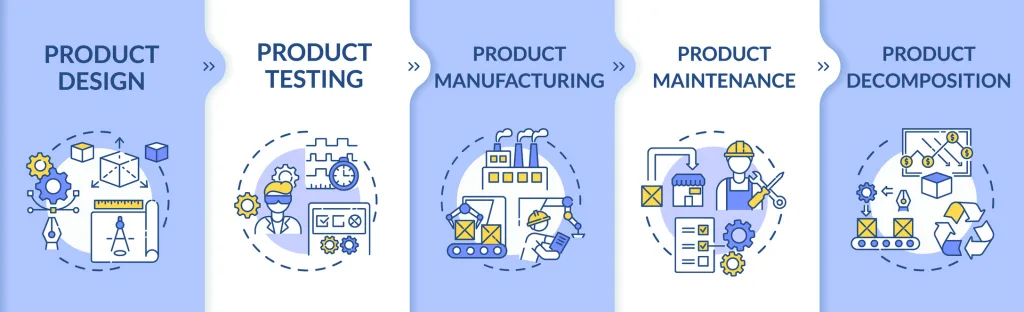

In the dynamic world of business today, the race to market and the agility to swiftly respond to shifting demands are crucial. Yet, as workforce numbers dwindle and technical expertise becomes scarce, many companies find themselves in need of extra contract manufacturing support—be it engineering, technical or manufacturing—across the critical stages of a product’s lifecycle.

Enter RG Group. With our unparalleled technical, engineering and manufacturing expertise, we become your secret weapon—the catalyst that accelerates product development and navigates demand fluctuations with ease.

We understand that each business is distinct, with its own set of operational hurdles and strengths. RG Group’s Contract Manufacturing offers flexible, on-demand support at any point in a product’s lifecycle. Our unique services and adaptable solutions are crafted to fit your unique requirements, ensuring you remain agile, efficient and profitable.

From design engineering to comprehensive manufacturing solutions, RG Group Contract Manufacturing serves as your singular point of contact, empowering you to focus on strategic growth and core business opportunities while we handle the rest.

We specialize in supporting the three key stages of product development:

Research & Development (R&D) | Production | Obsolescence or end of life

RESEARCH & DEVELOPMENT

From a start up with no manufacturing expertise to an established business launching a new product line, having the knowledge and resources to get a product launched in a timely manner are essential for success.

Our experience collaborating with customers includes design, engineering and First of a Kind production. We’ll aid your team in moving through project management, facilitating the process of transitioning an idea or concept to reality.

Our Research & Development capabilities include:

- Feasibility studies

- Breadboarding

- 3D modeling

- Prototyping

- Software development

- Component selection and Supply Chain development

- Testing and collaborative feedback loop

- MTBF analysis

- Production

PRODUCTION

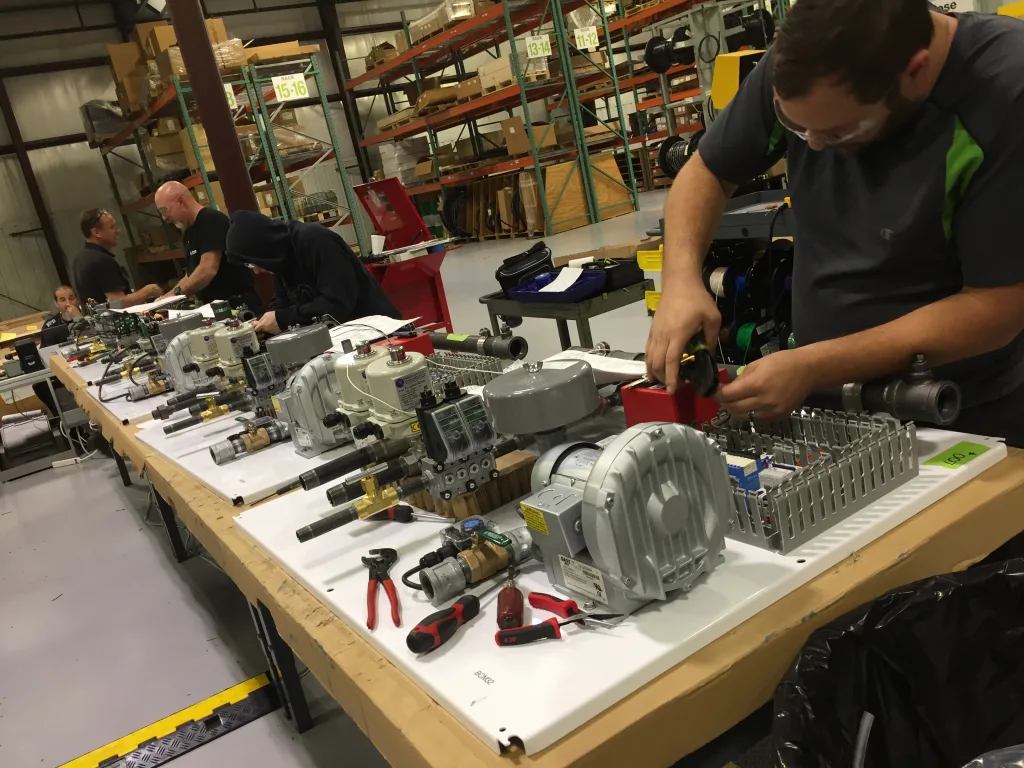

In today’s competitive landscape, the shrinking pool of available talent makes sourcing skilled production labor a distinct HR challenge. Coupled with the dynamic technical demands of advanced manufacturing processes and rising quality standards, manufacturers must now master a diverse range of skills to sustain a thriving and resilient production environment.

Additionally, manufacturers face hurdles such as early-stage product development and sudden spikes in demand. Partnering with a reliable manufacturing ally offers the flexibility to scale without increasing overhead, empowering corporate leaders to focus on strategic growth and core business pursuits.

Our Production capabilities include:

- Contract Manufacturing, sub-assemblies or complete company branded product

- Patent submittals

- Managing 3rd party approval processes

- Cost reduction and supply chain management

- Lifecycle testing

- Warranty fulfillment

- Aftermarket support

OBSOLESCENCE/END-of-LIFE

When a product or product line starts to see a consistent drop in demand, it’s time for companies to streamline their focus by removing the burden of maintaining a product at the twilight of its lifecycle. By outsourcing the support of these low-demand products, businesses can redirect their valuable resources towards more strategic goals. With RG Group’s Contract Manufacturing services, you can effortlessly transfer the responsibility of end-of-life products, ensuring exceptional customer service with minimal reliance on your current infrastructure and resources.

Our End-of-Life capabilities include:

- On demand manufacturing services

- Inventory management /supply chain maintenance

- Warranty fulfillment

- Warehousing and logistics

- Aftermarket engineering support

The benefit of relying on Contract Manufacturing from RG Group is our ability to provide the expertise you want in the time frame you need – allowing you to scale capabilities, reduce costs and focus on your core competencies.

- Full product lifecycle support from R&D to manufacturing and assembly

- ISO-certified, modern, technologically advanced facilities

- Tier 1 global supplier relationships and supply chain competencies

- Turn-key manufacturing and repair capabilities

Frequently Asked Questions

Q: What frequency of communication can I expect during the entirety of the project?

A: A consistent dialogue cadence is imperative for the project to progress as planned. RG Group is therefore committed to establishing and maintaining a regularly scheduled call each week so that all parties involved remain up to date on project status.

Q: What type of quality practices does RG Group adhere to?

A: RG Group maintains various certifications including ISO 9001 and adheres to best practice policies as monitored by our internal Quality Assurance Team. All certifications can be viewed at: Quality & Compliance – RG Group (rg-group.com)

Q: What happens if I have a problem after a project is completed or delivered?

A: All product related projects from RG Group come with a standard one-year warranty. Additionally, the RG Group engineering and product specialist teams are available for support after the point of sale to answer questions, trouble shoot problems and provide fee based, in the field support.

Why RG Group

Don’t let bandwidth, expertise or resources derail your product lifecycle journey.

From proof of concept to full production, we have the engineering, manufacturing and distribution capabilities to help you get your product to market.

Our Flexible Outsourced Manufacturing team can step in and seamlessly assist at any stage during your product’s development.

Contact us today to discuss where you need assistance and how we can help.