Robotic Palletizing System

STRATEGIC PARTNERS

Robotic Palletizing System

Meet Your New Palletizing Robot Solution

Redefine efficiency with a high payload, collaborative robotic palletizer built to automate your end-of-line packaging process.

The Leading High Payload Robotic Palletizing System

Are you dealing with a labor shortage? Do you need to run a more efficient warehouse? Our palletizing robot could be your answer!

This palletizing system combines a high payload cobot and our revolutionary palletizing robot base to provide a flexible solution that will streamline your packaging process. Designed by a robotics integrator, you can count on this system to merge the best of both old and new technology. It has the rigid reliability of an industrial palletizing system and the flexibility that only such an innovative product can offer.

A Cost-Effective and Collaborative Solution

We’ve built a solution that integrates seamlessly with your existing packaging flow and saves you money.

RG Group’s robotic palletizing system is a cost-effective alternative to standard palletizing robots. By using a robot, the “HD” component requires minimal integration and can be added to your existing packaging lines in under an hour.

When you invest in this system, you can expect:

Minimal Footprint

>> The robotic palletizing system requires no caging and can be easily added to lines with floor space constraints.

Quick Deployment

>> Your palletizing robot will arrive ready to work on the day of delivery! It requires only a standard outlet to operate –– that’s it!

Industry Leading ROI

>> RG Group’s palletizing system practically pays for itself. With the power to run two shifts a day, many of our clients see a high return on investment within their first year!

A Cost-Effective and Collaborative Solution

We’ve built a solution that integrates seamlessly with your existing packaging flow and saves you money.

RG Group’s robotic palletizing system is a cost-effective alternative to standard palletizing robots. By using a robot, the “HD” component requires minimal integration and can be added to your existing packaging lines in under an hour.

When you invest in this system, you can expect:

Minimal Footprint

>> The robotic palletizing system requires no caging and can be easily added to lines with floor space constraints.

Quick Deployment

>> Your palletizing robot will arrive ready to work on the day of delivery! It requires only a standard outlet to operate –– that’s it!

Industry Leading ROI

>> RG Group’s palletizing system practically pays for itself. With the power to run two shifts a day, many of our clients see a high return on investment within their first year!

Turn-Key High Payload Palletizing Robot | Benefits

Solve your labor issues fast with a palletizing robot. It not only has the ability to be quickly repurposed for future production requirements, but it also meets these requirements with no engineering needed.

Here are just a few reasons our robotic palletizing system is the undisputed industry leader:

Portability

>> This palletizing robot has built-in fork pockets embedded into the welded base for transportation. This means you can easily transport it by forklift or pallet jack.

Custom End-Effectors

>> We custom design your system based on your unique obstacles and advantages.

Collaborative Lifter

>> The pneumatics within the lifter base feature a collaborative rating to keep integration easy.

Multi-Pallet Reach

>> Stack pallets on each side of the chain for continuous and competitive operation. Your robot is built for multi-pallet reach!

Drag-and-Drop Software

>> You don’t have to be an engineer to operate our software. Easily build, edit, and save pallet configurations as production changes without writing a single line of code.

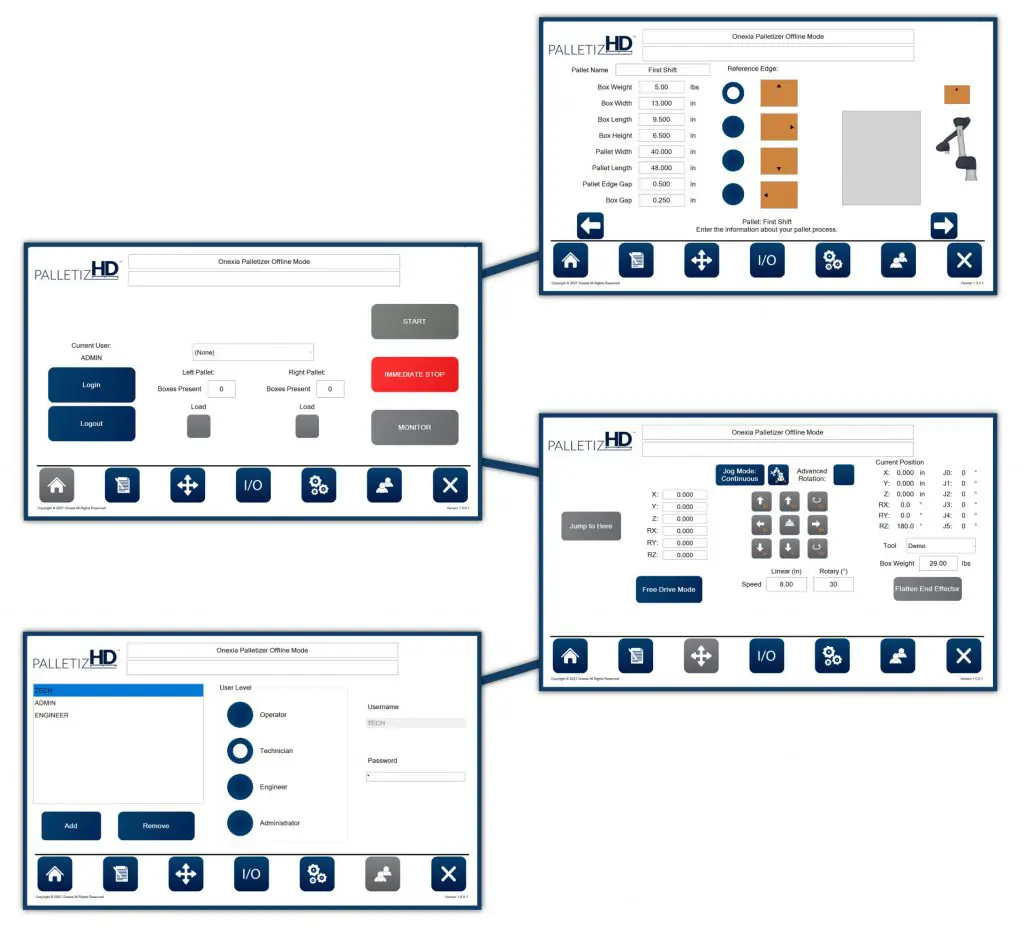

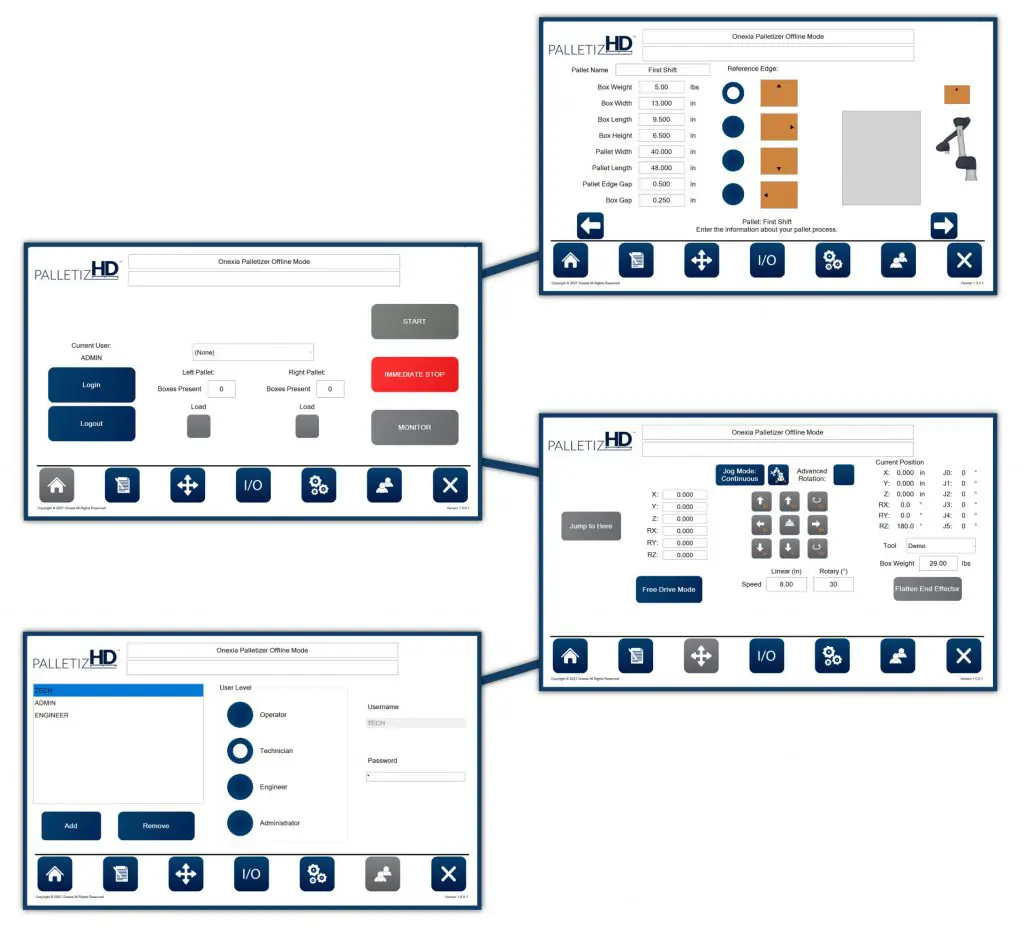

Simple Palletizing Software

Input and integrate custom pallet layouts. No coding is required.

You don’t need an engineering degree to make the most of your robotic palletizer. Every system comes with our state-of-the-art palletizing software installed on the embedded HMI within the palletizer base.

Easy to Use Interface

>> End-users have complete control of the entire robotic palletizing system through the embedded HMI on the lifter base.

Drag-And-Drop Pallet Building

>> It really is that simple. Build and save your custom pallet layouts without writing any code. Your system will update immediately.

Pallet Library

>> Your palletizing robot shifts gear whenever you need it to. Our software allows you to save and recall different pallet configurations to meet shifting production demands.

Administrative Controls

>> Keep your robot safe from disruption. Limit access based on user credentials to ensure only the right people can change configurations.

Build A New Pallet

Name the pallet and enter the specs of the case to be palletized.

Drag & Drop

Drag the boxes into place starting with the furthest point and working inward.

Add More Layers

Copy and paste or build each layer individually based on your pallet configuration.

Set Locations

Teach the pick location and the furthest place location. The “HD” does the rest!

Easy-to-Use Industrial Features

As an industry leader, we understand that each palletizing application is different. That’s why the RG Group palletizing robot comes ready to work with customizable features that assure your pallets exceed your expectations.

Slip Sheets

>> Easily add slip sheet layers to your pallets within the embedded software.

Label Orientation

>> Keep shipping labels oriented correctly for scanning during final shipment.

Reject Station

>> Inspect boxes for labels or defects before palletizing.

THE HD ADVANTAGE

>> RG Group’s robotic palletizing systems are HD. What does that mean? That means it optimizes your end-of-line productivity by automating repetitive, difficult work that exceeds throughput expectations.

>> The high payload cobot features a 38 lb payload. Your “HD” robotic system can handle heavy cases that are difficult for humans to stack. By picking multiple cases at once, the palletizing robot advantageously increases your output rate.

>> With an increased vertical reach, this “HD” robot is capable of stacking pallets up to 90 inches in height by utilizing the built-in collaborative lifter.

HIGH-PAYLOAD

H-SERIES COBOT

Most powerful cobot on the market.

Key Features:

» Master+ Safety

» Master+ Force Control

» Master+ Work Management

» Master+ Setup

Doosan Robotics COBOTs | Simply The Best

Doosan Robotics offers the world’s most diversified lineup of cobots with a load capacity of 6 to 15 kilograms and a working radius of 0.9 to 1.7 meters. Doosan Robotics’ COBOTs are the easiest and most affordable solution to enable smart factories because it requires lower set-up and investment cost than industrial robots. COBOTs can work alongside human operators without safety fences thanks to highly sensitive torque sensors.

Doosan Robotics enables smart factories by developing and manufacturing COBOTs that are capable of doing complex tasks based on precise detection skills via torque sensors, excellent safety performance, and detailed power control.

Sensitive and Safe

>> Maximum safety to protect your team, machine, and robot

Talented and Skillful

>> Cutting-edge precision force control built for speed and accuracy

Reliable and Innovative

>> Lightweight, durable, and developed with innovative technology for easy control

Intuitive and Simple

>> Intuitive interface similar to smart devices that are easily operated by anyone

Discover The Difference Today

Overcome the labor shortage while saving time and money. The RG Group robotic palletizing system is your turnkey solution for a streamlined packaging process and high return on investment. Easy to integrate and even easier to operate, your system will serve you from the day it arrives.

Contact us today to learn more and receive a quote!