Our Motion Control & Fluid Handling Solutions

Our solutions

Have a question?

You can count on RG Group for excellent quality and service

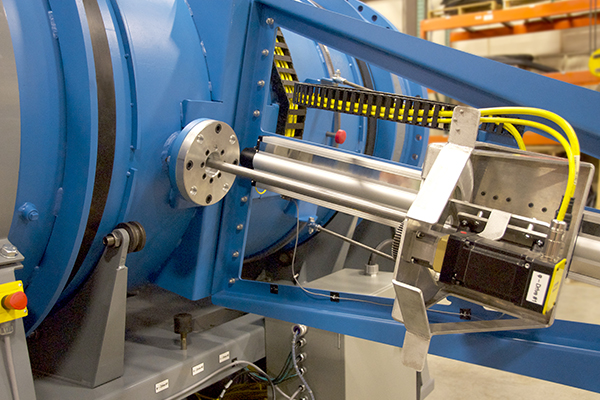

Pneumatic, hydraulic, electromechanical, filtration, hose, valves and fittings for any industrial and instrumentation application you can imagine.

What we do

Automation Customer Spotlight

Our solutions

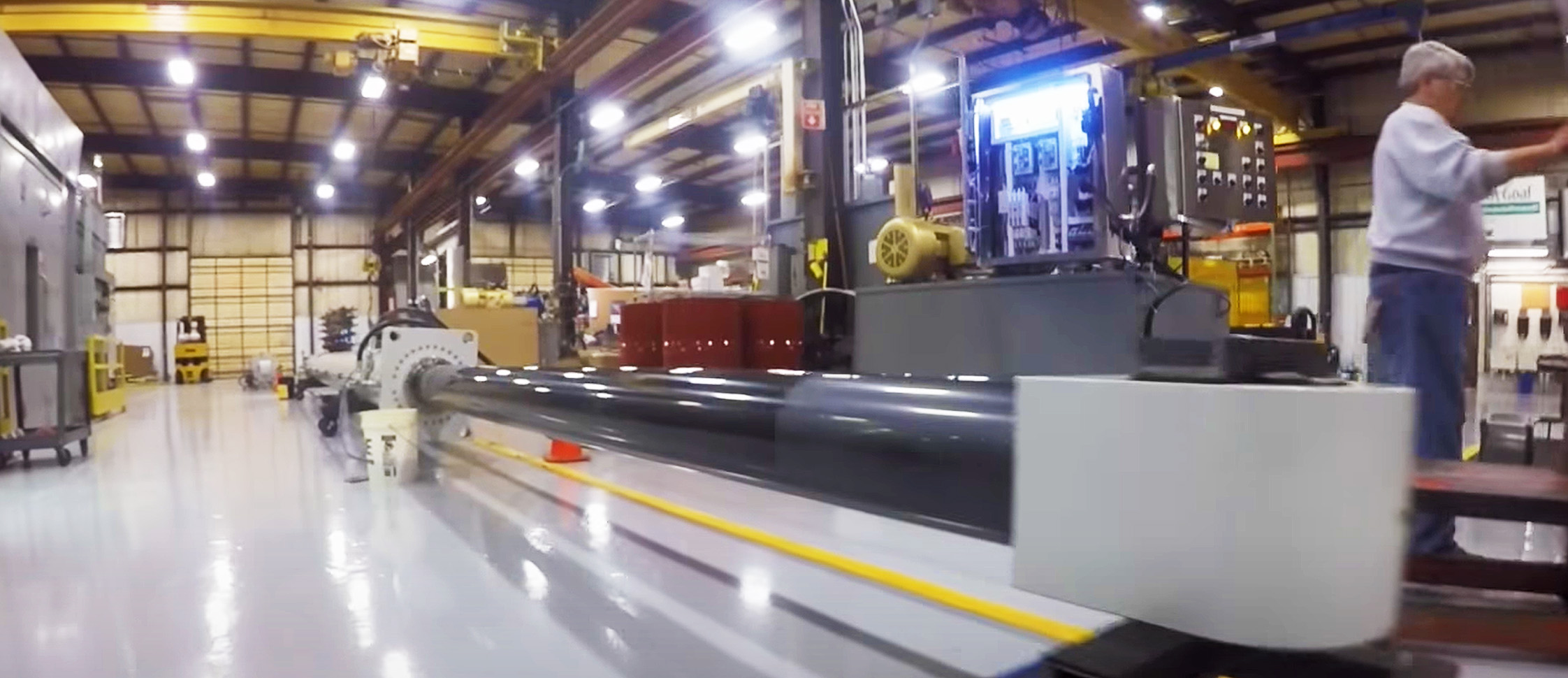

We do what it takes to get your system up and running, whether you need scheduled maintenance, installation or system troubleshooting.

Learn more

We do what it takes to get your system up and running, whether you need scheduled maintenance, installation or system troubleshooting.

Learn more

We do what it takes to get your system up and running, whether you need scheduled maintenance, installation or system troubleshooting.

Learn more

We do what it takes to get your system up and running, whether you need scheduled maintenance, installation or system troubleshooting.

Learn more

We do what it takes to get your system up and running, whether you need scheduled maintenance, installation or system troubleshooting.

Learn more

You can count on RG Group for excellent quality and service

Contact us today