Most hydraulic-based systems utilize accumulators for supplemental pump flow, soothing ripples from the pump, or storing energy in the system. When it comes to Wind Turbines, in particular, accumulators can be utilized in all three cases – making them critical to the uptime of the turbine. Because of this, having a quality and reliable bladder accumulator is critical. In this article, we’ll break down the use of bladder accumulators, why this part’s upkeep is important, and the best bladder accumulators on the market.

What is a Bladder Accumulator?

Accumulators play an essential role in the operation and performance of wind turbines, storing hydraulic energy specifically for blade braking and pitch control functions. One of the many kinds of hydraulic accumulators out there are Bladder Accumulators. As its name suggests, bladder accumulators consist of a rubber bladder in the pressure vessel that separates the hydraulic fluid from the compressed gas. Bladder-style accumulators are a popular choice to use within wind turbines because of their universal application, durability, and cost-effectiveness, to name a few.

Like all accumulators on the market, bladder accumulators require regular maintenance to regulate the proper nitrogen pre-charge levels. This is because the material that is used has a large surface that is gas-permeable and can lose nitrogen through the bladder’s surface. While this is a simple repair, this is where those see an advantage of utilizing a piston accumulator. With the reduced surface area of the seals, the piston can hold the nitrogen pre-charge much longer than the bladder-style, not costing the time and money to spend recharging the nitrogen.

Whether you decide to utilize a bladder, piston, diaphragm, or other type of accumulator for your wind turbine, choosing a reputable supplier is vital to get the life, quality, and reliability out of your parts.

Where to Buy Quality Bladder Accumulators?

Sourcing high-quality accumulators from a reputable and trustworthy supplier should always be your top priority. Parker, a global leader in control and motion technologies, offers a range of hydraulic accumulator models that deliver precise regulation designed to regulate the performance of bespoke hydraulic systems. Parker’s Olaer division is known for making quality bladder accumulators for Wind Turbines. As the industry’s original, Parker’s bladder accumulator maintains the highest quality with their in-house bladder-molding operations suitable for various fluids and temperatures. Their newly developed global bladder models are engineered to meet all global requirements and certifications with in-house manufacturing to ensure they meet their highest quality and performance standards.

With its innovative and value-added design, the Parker is interchangeable with many of the OEM models while also having several advantages over them, including:

- Replaceable bladders

- Multiple compounds to meet lower temperature requirements

- AMSE versions for the US market

Along with Parker’s complete selection of bladder accumulators, they provide Bladder replacement Kits to repair existing accumulators without removing the shell from the system. Parker’s bladder replacement kits have a list of unique features specifically for the wind industry to ensure a long life, low nitrogen gas permeation, and a wide operating temperature range.

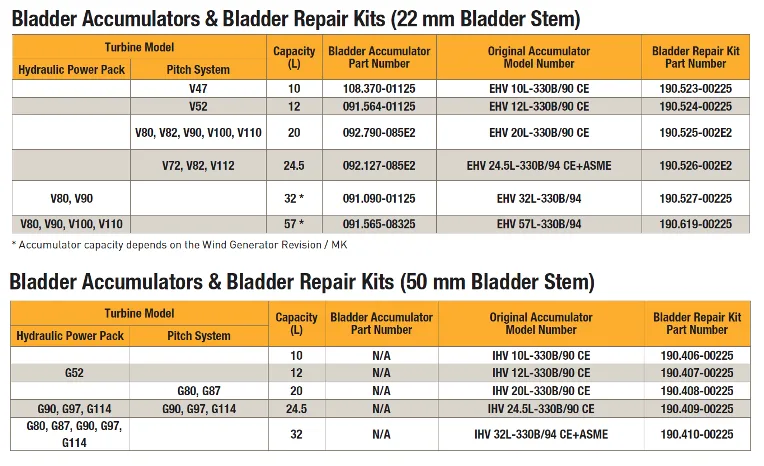

Here is a short list of some of the accumulators and repair kits you might find for your model Wind Turbine:

Accumulator & Wind Turbine Maintenance

A wind turbine is only as good as its parts and maintenance. If you operate or service a Wind Turbine facility, over time, there will be a need to replace or repair certain hydraulic systems with new, high-quality parts. Additionally, if your wind turbine utilizes bladder-style accumulators, it will need regular maintenance whether it’s refilling the nitrogen pre-charge levels, repair, or replacement. Servicing your accumulator and maintaining the proper nitrogen pre-charge is essential to the wind turbine’s performance, sourcing the right parts and working with the right distributor.

At RG Group, we service both OEM and maintenance providers – providing service, replacement components, and upgrades for wind turbine hydraulic systems. Whether it’s filters, valves, or accumulators, we can help you replace or offer better performance from your hydraulic parts.

Improve Your Bladder Accumulators from Parker at RG GroupRG Group?

RG Group proudly supplies the industry’s finest products and solutions as a Parker partner and distributor. With Parker’s complete selection of bladder accumulators able to meet virtually every application on today’s wind turbines, we will match you with the right hydraulic solutions.

RG Group has been designing and building hydraulic projects since 1956. We are committed to excellence in engineering and quality control and will always deliver your products on time. We offer flexible outsourced manufacturing and provide you with in-depth and long-term support, assisting you through the design phase to engineering and production, field support, and more.

To discuss your needs in the Wind Turbine market or need to extend the life and maintenance intervals for your bladder accumulator model, contact Steven Reynolds at steve.reynolds@rg-group.com.

Learn more by visiting RG Group’s hydraulics solutions, and downloading the Parker Wind Turbine product catalog.

Find Wind Turbine Parts from Parker at RG Group

Check us out at https://www.rg-group.com/solutions/hydraulics/ or download the Parker Wind Turbine product catalog at https://www.parker.com/ParkerEnergy_WindTurbine. With thousands of parts at our disposal, the chances are high we’ll have what you need, when you need it. If you want to discuss your needs in the Wind Turbine market, please contact me at steve.reynolds@rg-group.com.