In a prior blog we discussed replacement of bladder accumulators and how this has been a good option for many applications within the wind turbine market. The use of these style accumulators is critical to the uptime of the turbine as bladder, or diaphragm accumulators might not be the best choice depending on a variety of factors.

Are your accumulators living up to their life expectancy or failing prematurely?

Diaphragm style accumulators are not repairable. This is why some wind turbine operators have switched to bladder accumulators. An option to diaphragm style accumulators are piston style accumulators. These come in both repairable and non-repairable versions with multiple compounds to meet lower temperature requirements. There are AMSE versions for the US market and CE for most of the rest of the world. Parker has been making quality accumulators for wind turbines for many years, but turbines come from all over the world in varying designs and quality. The OEM accumulators may not be giving you the life expectancy that is desired. The advantages of changing to a piston accumulator is a higher life expectancy and reduced risk of premature failure.

Where and how are you using accumlators?

The two main systems that use accumulators are blade braking and pitch control. Both applications use the accumulators to store hydraulic energy for use in case of loss of control pressure or hold a pressure without the need for additional power.

The issue with using a diaphragm accumulator is the failure mode, which is often catastrophic with no warning signs. The diaphragm usually tears. Once this device fails there is an immediate loss of control because the hydraulic pressure dissipates, and the system will no longer work. This could cause the wind turbine to run away and cause significant damage.

Do you need replacement or upgraded wind turbine parts?

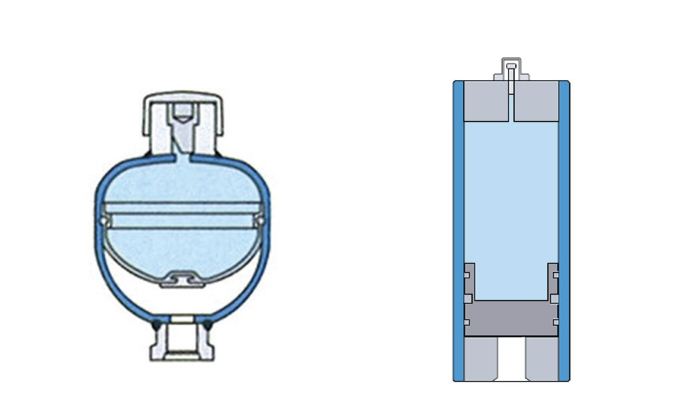

If you have diaphragm or bladder style accumulators, you will need regular maintenance to maintain the nitrogen pre-charge. This is because the material used has a large surface that is gas permeable and can lose the nitrogen thru the diaphragm or bladder surface. This is where the advantage of the piston accumulator really shines. As the surface area of the seals is greatly reduced, sometimes as much as 15 times less, and therefore can hold a pre-charge much longer than the other styles of accumulator. As you can see in similar volume accumulators, diaphragm on the left and piston on the right, the seal surface is far smaller with the piston accumulators.

Although the piston accumulators cost more, the savings is usually worth the time the maintenance personnel have to spend recharging the nitrogen. If there is a full failure of the diaphragm, then for sure you would have wished you would have switched to a piston accumulator no matter what the fractional cost would have been for a better product with non-catastrophic failure modes.

I would also like to add that Parker put out a fantastic White Paper titled “Improve Wind Turbine Safety with a Piston Accumulator that delves further into why a change from a Diaphragm to a Piston style accumulator might be a good idea for both blade braking and pitch control. You can check that out here.

Whether you choose a repairable or a non-repairable piston accumulator, you will be improving safety and the life span of your wind turbine.

Contact me at steve.reynolds@rg-group.com. and we can discuss your particular needs to extend the life and the maintenance intervals for your model and site.

Why Choose Parker and RG Group?

More than 100,000 operational wind turbines have Parker products, demonstrating their expertise in this still-emerging energy resource. It is not unusual for plant owners and operators to inquire about the operating record of any new component proposed as a replacement. Potential suppliers expect those questions. A potential user should begin by investigating the track record of the supplier. Parker Hannifin has certainly been recognized as a global provider of motion and control technologies, particularly hydraulic controls, for over a century. Control of hydraulics has been at its core for almost as long.

RG Group has been around since 1957, distributing and incorporating Paker parts and technologies in their solutions since its inception. Our team of product specialists, engineers and fulfillment staff ensure that the Trusted Expertise the company is known for is delivered upon every day.

Find Wind Turbine Parts from Parker at RG Group

Check us out at https://www.rg-group.com/solutions/hydraulics/ or download the Parker Wind Turbine product catalog at https://www.parker.com/ParkerEnergy_WindTurbine. With thousands of parts at our disposal, the chances are high we’ll have what you need, when you need it. If you want to discuss your needs in the Wind Turbine market, please contact me at steve.reynolds@rg-group.com.