A poppet valve is a type of directional valve which utilizes a ball and seat instead of a traditional spool. You may not realize it, but you take advantage of poppet valves every day when you drive to work. Without poppet valves, your car wouldn’t be able to function! (Assuming you have a combustion engine)

Poppet valves act like check valves, but with the ability to allow free flow across the seat. Plus, in certain configurations, poppet valves can direct the flow of media to ports on the valve body like a traditional directional valve. Utilizing a poppet valve in your hydraulic or pneumatic circuit can allow you to have the features of a check valve, but with the versatility of a directional valve.

Poppet valves have many advantages, but here a few:

• Check Valve and Directional Valve in one body

• Little or no leakage across the seat

• Faster response rates

• Higher flow rates than a similar sized spool-type valve

• Longer product life • Less maintenance!

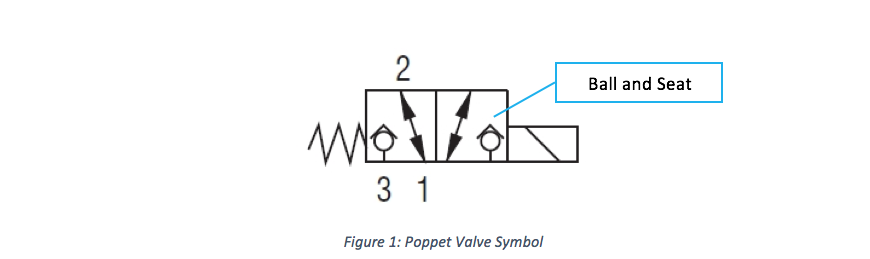

When reading a hydraulic schematic, you can identify a poppet valve by the ball and seat, similar to a check valve, but located within a valve body box. See Figure 1 for a Poppet valve symbol. The full description of the valve shown is a solenoid-operated, 3 way 2 position (3/2), spring-return poppet valve. In the normal position, port 1 is open to 2 while port 3 is sealed off. When the electric solenoid is powered, port 3 is open to 2 while port 1 is sealed off. When the solenoid releases, the valve returns to the normal position.

If you’re interested in getting more information about poppet valves, feel free to contact me! I’d be glad to discuss your application and see if you could benefit from utilizing a poppet valve.

Brian Robison

Mechanical Engineer